Air Purifier

The air purifier, which is used to purify indoor air in homes, is fitted with an electrostatic charge on the ultra-fine meltblown fiber, which enables it to effectively remove gas compounds (formaldehyde, acetaldehyde, ammonia, formic acid, and toluene) and has a low-pressure, high-efficiency dust ollecting capability. In addition, it possesses antibacterial (anti-fungal, anti-viral, and anti-allergic) properties.

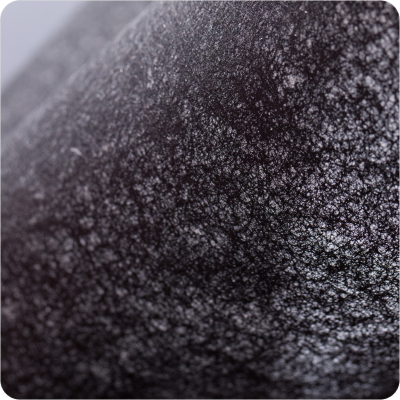

Automotive

Carbon media products are composite media consisting of activated carbon with a large specific surface area which is combined with carbon impregnated with various metals, metal salts, or organic substances and meltblown, a highly efficient electrostatic non-woven fabric. Having many functionalities, they are able to selectively remove gases that clients require while also eliminating fine dust.

Power Plant

Made of a filter material with high porosity, high efficiency, high collection amount, and water resistance required for high output and high-efficiency power generation, this product combines filter paper and meltblown nonwoven fabric, resulting in a specialized material that can be applied in specific industrial processes.

Fuel

Moisture and impurities in fuel filters can result in engine oxidation, wear and tear, and malfunction of the injection system and sensors. By efficiently eliminating moisture and impurities, Clean & Science’s Cellulose and Meltblown media are optimized to sustain the stable operation of fuel injection systems.

Air

The filtration paper for Internal combustion engines and industrial air cleaner filter prevents engine abrasion/wear by passing clean air without foreign substance; thus, helps to improve fuel efficiency of vehicle. Clean & Science is manufacturing various types of best filtration paper products that meets customers’ needs which satisfies proficiency of ventilation and efficiency.

Oil

The evolution of the filtration paper of lubricants continue to meet the customers’ demands for durability and improvement of fuel efficiency on internal combustion engine. The products of Clean & Science are made of media that has long life and heat resistance depending on the usage. From design to mass production, Clean & Science owns technology and continuing research and development on cellulose and cellusose+synthetic fiber to meet the customers’ demands.

Fuel

Diesel, biofuels, kerosene, jet fuel, and gasoline all include impurities that can cause engine oxidation, wear and tear, and malfunction of the injection system and sensors. Clean & Science manufactures media optimized for preserving the steady operation of fuel injection systems by efficiently eliminating impurities utilizing the Single & Dual Phase (Composite) technology applied to various materials including cellulose, micro glass, and synthetic fibers.

EDM

The filtration media for wire-cutting electrical discharge machines (EDM) filters metal particles in water that are generated during the process of electrical discharge. Clean & Science manufactures high performance filtration media by using over 90% of synthetic fiber in order to prevent problems in the wire-cutting EDM from flow of unfiltered water.

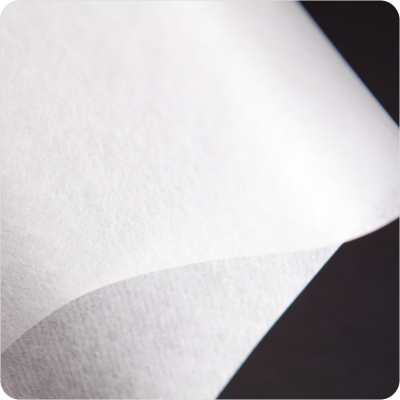

Particle

It is used as a medium in vehicle cabin filters, air purifier filters, vacuum cleaner filters, air conditioner medium and HEPA filters, and gas turbine filters in power plants to remove airborne particles. These materials are produced utilizing the meltblown method and electrostatically charged ultra-fine fibers to provide low-pressure high-efficiency performance. In addition, it is a product that may be coupled with materials that have antibacterial and deodorization capabilities to not only remove fine dust but also add antibacterial and odor-removal.

Liquid

The water treatment filter that are used for industry and home filters fine particles present in liquid. The main material of the filter, melt-blown, has excellent performance of impurity removal and long use life by maximizing the porous structure. It is mainly used for production lines of semiconductor and food company due to its excellent mechanical strength of thermal fusion and filtration precision.

Sound Absorber

This product absorbs engine noise flowing into the interior from outside the vehicle and friction noise between the tires and the road during the driving. This product’s high sound-absorbing power satisfies the requirement of automobile manufacturers.

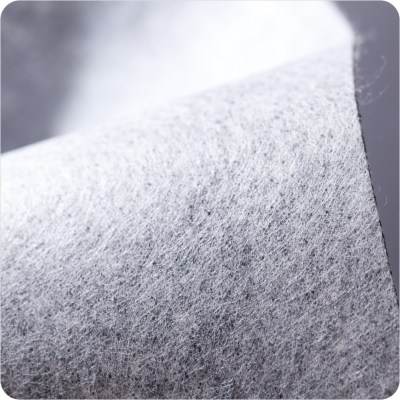

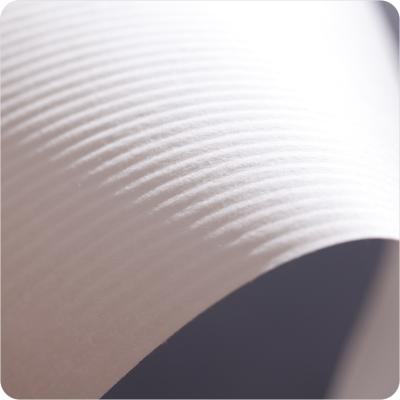

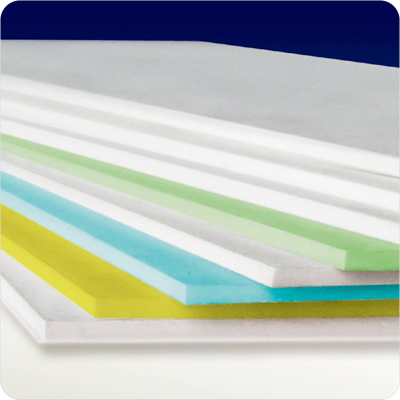

Thermal Bond

This is a non-woven that are combined with thermal bond and needle punch, applied for the support of the filter, pre-filter for air conditioning, and electrostatic cabin filter. This specialized product is tailored for high permeability and workability based on customers’ request.

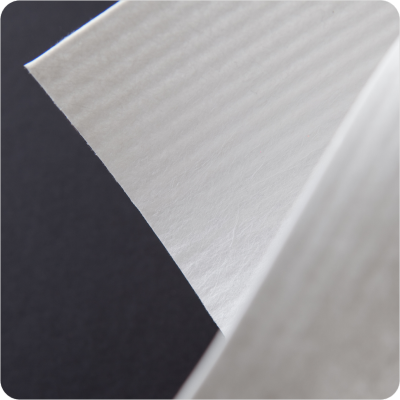

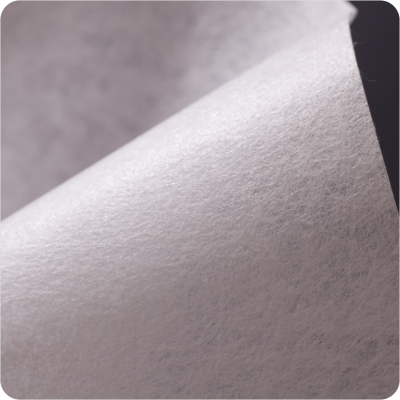

Needle Punch

Using a specific needle-punching technique, the product is created by combining randomly ordered fibers created by the up-and-down reciprocating motion of a particular needle-punching machine into a three-dimensional random structure. According to the punching frequency of the needle, needle density, and production speed, the product’s qualities and functions can be manufactured in a variety of ways.

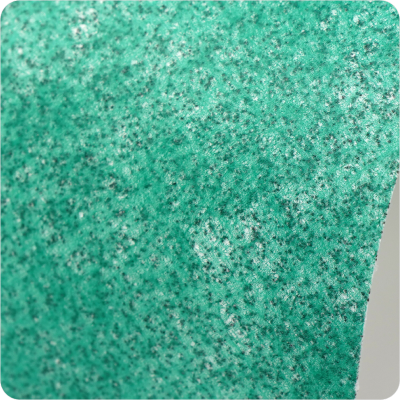

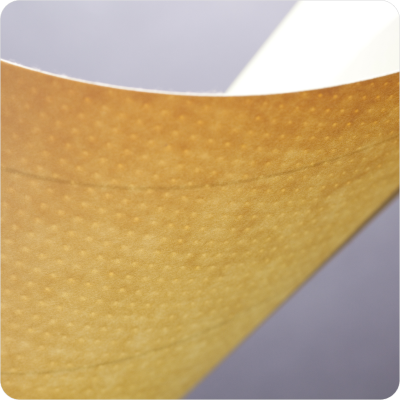

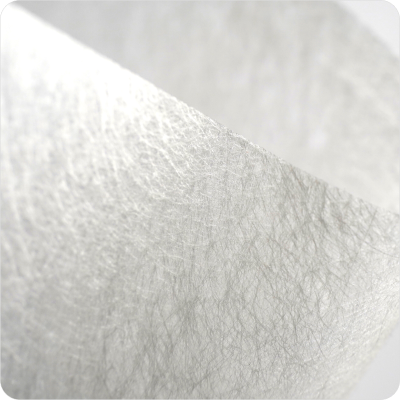

Electrostatic Non Woven

It is a material used in automobile cabin filters, masks, and air conditioner filters to remove airborne particles. This material is produced by weaving together stable fibers and applying an electrostatic charge. In comparison to meltblown material, it has a lower pressure drop and a good dust-holding capacity due to its bigger fiber diameter and greater basis weight.

UHMW

Due to its exceptional wear resistance and tensile strength, UHMW film and tape are utilized in a variety of mechanical applications, including machine settings and blasting, where friction may frequently occur.

PTFE

Due to their non-stick, chemical resistance, heat resistance, and wear resistance, PTFE film and tape are used in a wide range of industrial situations, such as battery electrodes and machine packaging. They are also used in a wide range of applications, such as protecting household cooking utensils and tools.