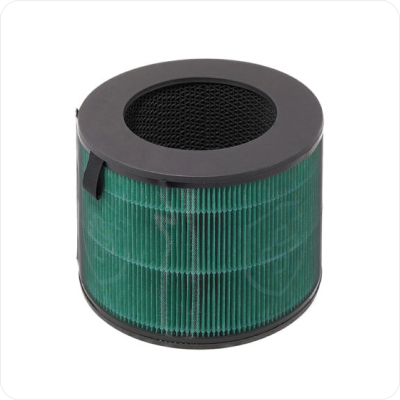

Particle

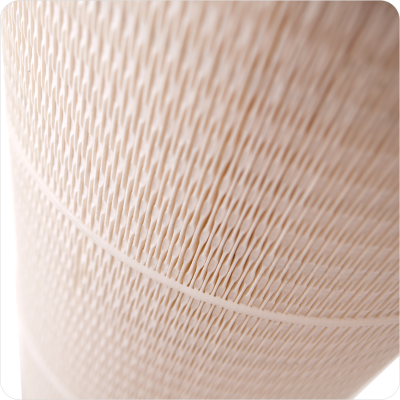

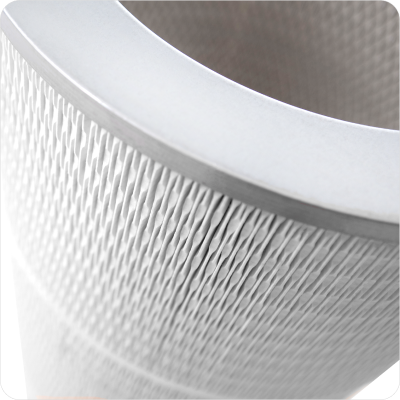

This product is utilized in air purifiers that are used to filter the air inside of homes, achieving high efficiency at low pressure by imbuing ultrafine meltblown fibers with an electrostatic charge.

It can also have antibacterial (anti-mold, anti-virus, anti-allergy) and deodorizing properties.

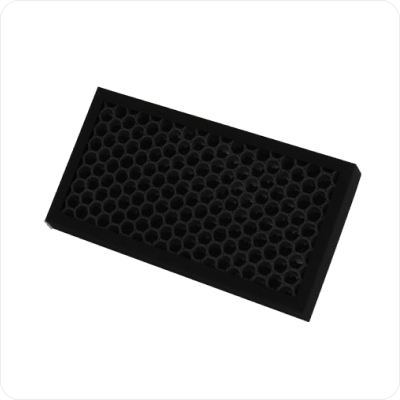

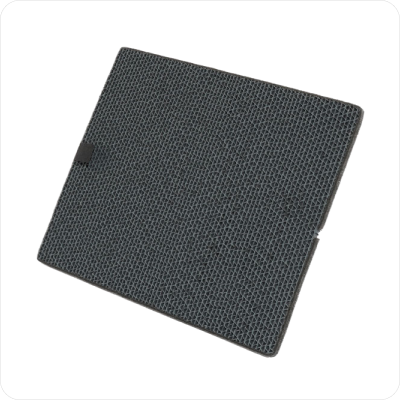

Deodorization

Using Clean & Science’s adsorption technology is highly effective at eliminating hazardous gases. It can be provided by both domestic air purifier standards (CA) and international certification standards, such as those in China. It has high efficiency in removing formaldehyde, acetaldehyde, ammonia, acetic acid, and toluene, which are the five gases for CA certification, and it is possible to supply deodorizing filters with excellent removal performance for other harmful gases such as benzene, sulfuric acid gas, nitrogen dioxide, and ozone. Moreover, product manufacturing and supply using Combi fabric, which implements both particle pollution and deodorizing performance through Clean & Science’s composite media, are possible.

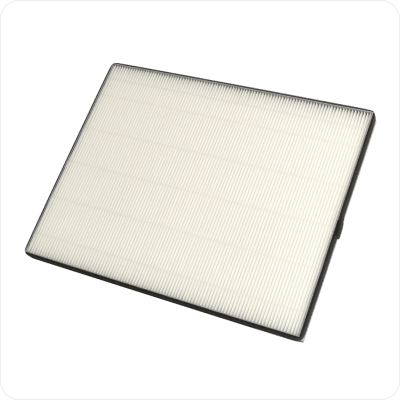

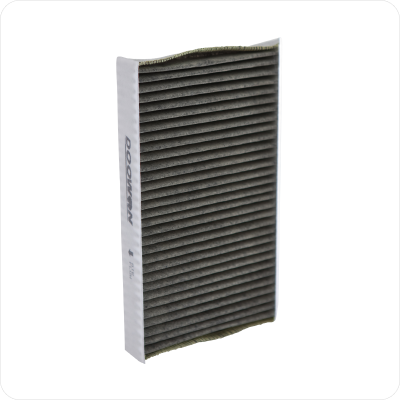

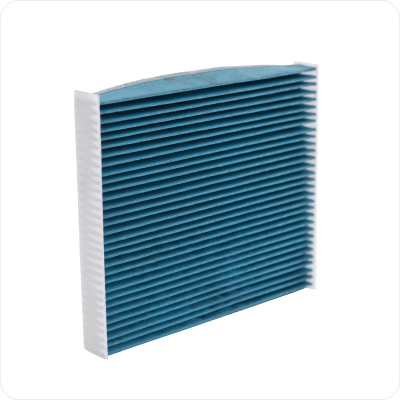

Particle

This is a car indoor air purification product for removing particulate matter (fine dust, mold, bacteria, pollen, etc.) that enters the interior of a car from the exterior.

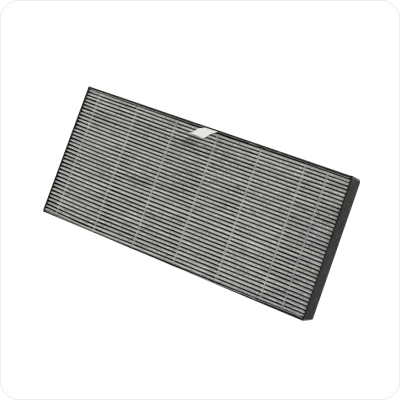

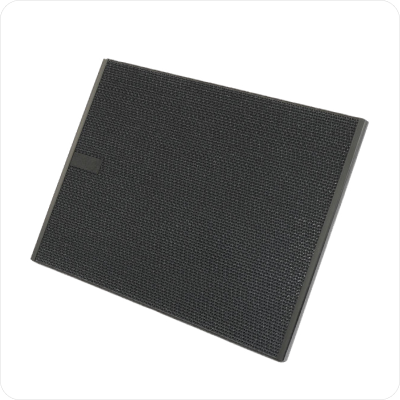

Combi

This car indoor air purification product can remove particulate matter (fine dust, mold, bacteria, pollen, etc.) and gaseous matter (NOx, SOx, VOCs, etc.) that enter the interior of a car from the exterior.

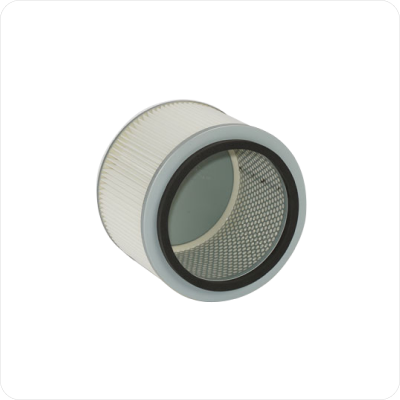

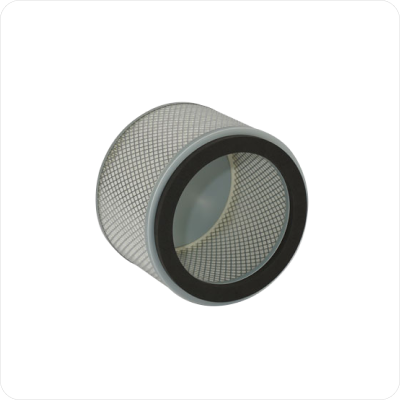

Particle

It is a high-efficiency and antibacterial product that stops harmful germs and particles entering into the vacuum cleaner from escaping and has the benefit of low-pressure loss to boost dust suction power.

Particle

It has a particle capture efficiency range of 50-95% based on 0.3μm standards, similar to that of an air purifier, and is used in air conditioners to improve indoor air quality.

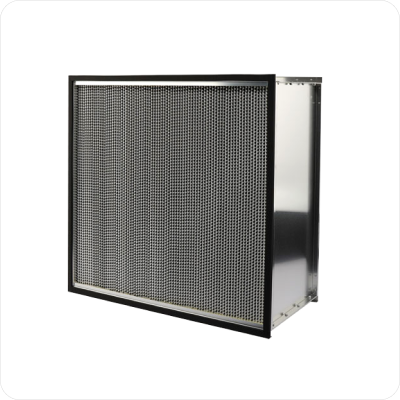

ULPA

It has a particle capture efficiency of 99.999% or higher based on 0.1μm standards and is applied to manufacturing processes that require high cleanliness, such as semiconductors, LCDs, and pharmaceuticals, with Clean Room Class 100 or lower as well as FFU systems.

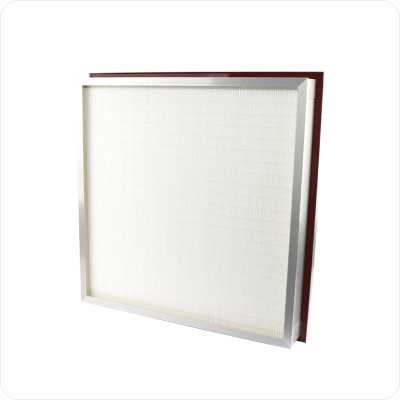

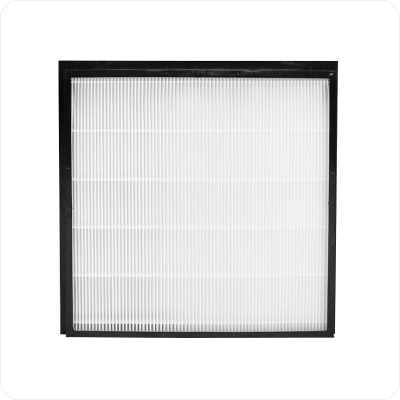

HEPA

It has a particle capture efficiency of 99.97% or more based on 0.3μm standards and is applied to manufacturing processes that require high cleanliness such as semiconductors, LCDs, and pharmaceuticals.

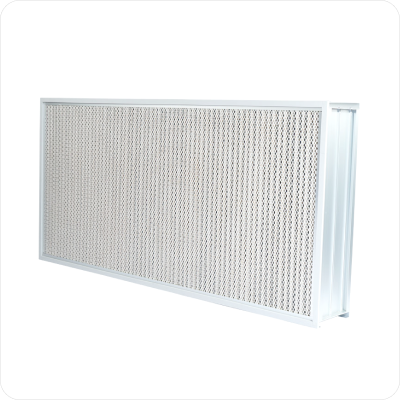

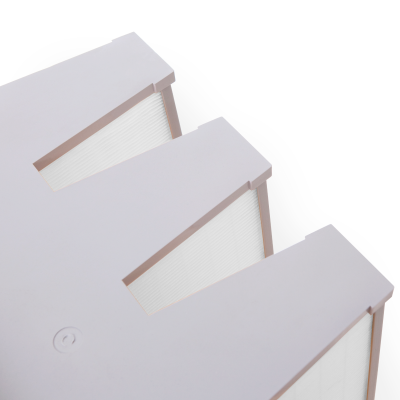

Medium

It has three types of particle capture efficiency: 65%, 85%, and 95% according to the dust spot method, and is mainly used for HEPA filter pre-treatment in Box/Flange type.

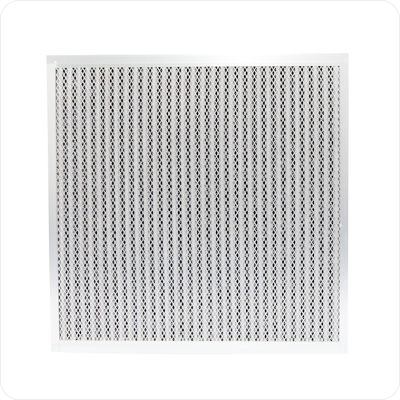

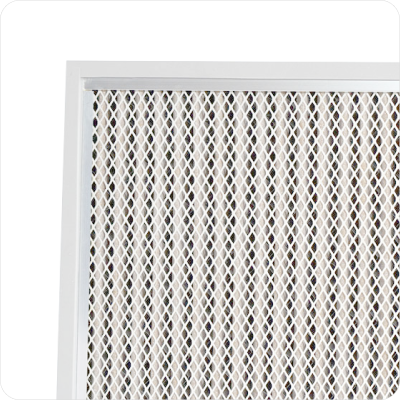

PRE

It has a particle capture efficiency of 85% according to a gravimetric method and is applied to medium pre-treatment in Panel and Pleat Types.

Chemical

1) It can be applied to industries that emit malodorous and harmful gases, especially for ultra-precision manufacturing processes such as semiconductors and displays.

2) In particular, it aims to selectively remove NH3, O3, Sox, Nox, and VOC, which are the direct causes of increased product defectsx in the semiconductor and display industry, and design reviews can be conducted based on high removal efficiency of 90% or more and requested service life.

3) It is possible to produce and supply chemical filters that control single and complex gases depending on the application process, starting from activated carbon adhesion.

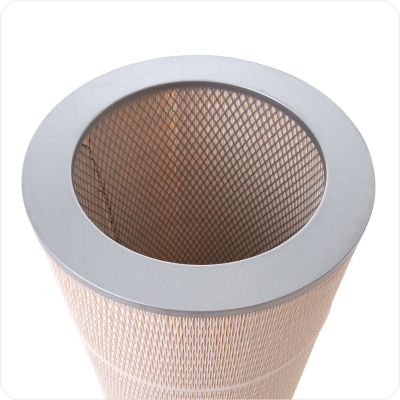

Conical

It has a particle capture efficiency of 60-99.5% and has the advantage of a long lifetime due to its high capture capacity.

It is also easy to handle (replacement, transportation, and storage) and can be applied as an intermediate and final filter in gas turbines.

Cylindrical

It has a particle capture efficiency of 60-99.5% and has the advantage of a long lifetime due to its high capture capacity.

It is also easy to handle (replacement, transportation, and storage) and can be applied as an intermediate and final filter in gas turbines.

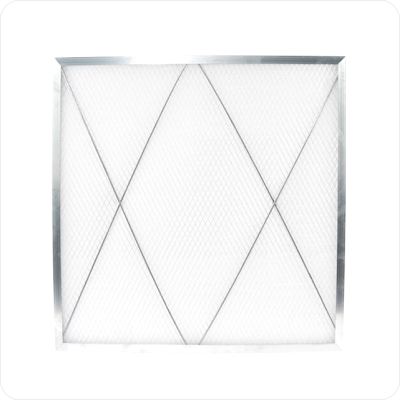

V-BANK

It has a particle capture efficiency of 60-99.5% and has the advantage of a long lifetime due to its high capture capacity.

It is also easy to handle (replacement, transportation, and storage) and can be applied as an intermediate and final filter in gas turbines.

Standards Series

The Standards Series is a filter with a pleated structure of Dia 69mm (2.7 inches). The main media consists of Polypropylene, PES, Nylon, Glassfiber, and hydrophobic/hydrophilic PTFE. It is produced by heat bonding without the use of solvents and manufactured in a clean room. The filter’s specifications and explanations can be found in the respective catalog.

HIGH Flow Series

High Flow Series is a pleated filter with a diameter of 83mm (3″). The main media consist of Polypropylene, PES, Nylon, and hydrophobic/hydrophilic PTFE. It is designed with a unique flow rate (100L/min) suitable for LCD and display applications. This filter is suitable for high-capacity processing due to the increase in the capture area and longer lifespan. The filter’s specifications and explanations can be found in the respective catalog.

ULTRA Flow Series

ULTRA Flow Series is a pleated filter with a diameter of 130mm (5″). The main media consist of Polypropylene, PES, and hydrophobic/hydrophilic PTFE. It is designed with a unique flow rate (200L/min) suitable for LCD and display applications. This filter is suitable for high-capacity processing due to the increase in the capture area and longer lifespan. The filter’s specifications and explanations can be found in the respective catalog.

SUPER JUMBO Series

Super Jumbo Series has two types: Dia 155mm Type (JSF Super Jumbo) and Dia 165mm Type (JST Super Jumbo). This filter is suitable for applications requiring a flow rate of more than 80m³/hr. It is designed to maximize flow rate and capture volume while minimizing installation space, operating costs, and maintenance. The filter’s specifications and explanations can be found in the respective catalog.

DEPTH FILTER

Pre-filters are filters that can be used for various purposes. There are String Wound, Nonwoven Wound, and MB (Melt Blown) Depth Filters.

This filter can utilize 100% of the space due to its deep filtration method and is chemically safe because it is made of Polypropylene.

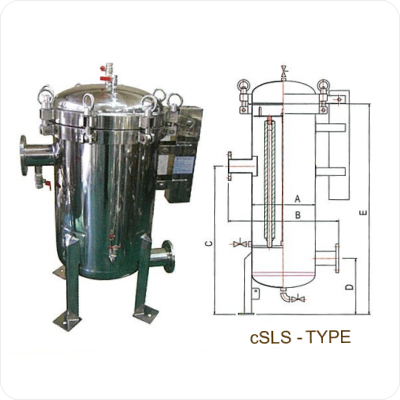

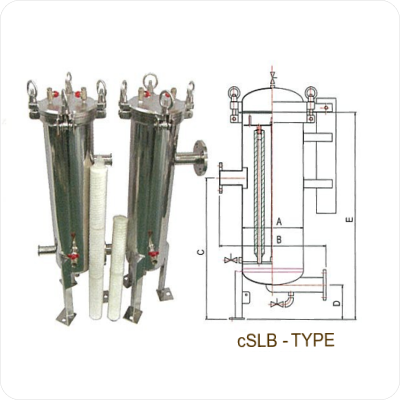

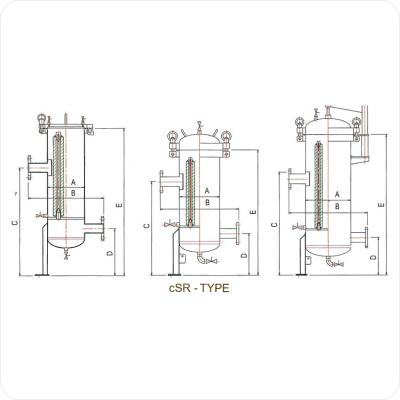

FILTER HOUSING

Filter Housings can be designed to meet the user’s requirements, from basic standard configurations to custom designs.

It is constructed with the most compact and stable structure and can be manufactured using various materials.